wbulte

Active Member

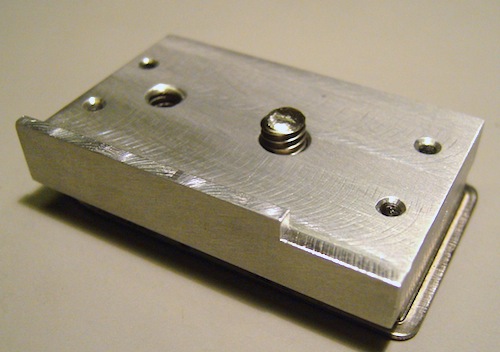

I am planning to machine my own quick release plate for the original HB tripod quick release. From an old 500-series I have scrounged the stainless steel QR plate, I now plan to mill a aluminium spacer plate to fit between the camera and the stainless steel plate.

For inspiration purposes I am looking for some detailed pictures of the original HB QR plate for Xpan.

Can some kind soul post some please?

Wilko

For inspiration purposes I am looking for some detailed pictures of the original HB QR plate for Xpan.

Can some kind soul post some please?

Wilko